About us

The core technology team of AMS MEMTECH has over 30 years of experience in nanofiltration membranes and Experience in research and application of ultrafiltration membranes, with decades of work experience in well-known overseas membrane companies Experience. Our application technology development in various industries, through cooperation with engineering companies, Promote the application of membrane separation systems in various industries in industry.

AMS MEMTECH products have more application advantages compared to other similar products in the following aspects: . Stable chemical properties in extreme media: The pH range is 0-14 and strong acids and bases that are not covered by pH, such as H2SO4 with a concentration of 20% H3PO4, HCL, and NaOH and KOH with a concentration of 20% .Various organic solutions (such as methanol, propanol, ethanol, acetone, hexane, tetrahydrofuran, ethyl acetate, methanol) .Benzene, dichloromethane, acetonitrile, etc.) .Stable tolerance to temperatures up to 80 ° C and operating pressures of 70 bar .High metal retention rate .Strong separability .Large processing capacity .Long service life Please refer to the product content section for specific parameter introductions for each membrane model.

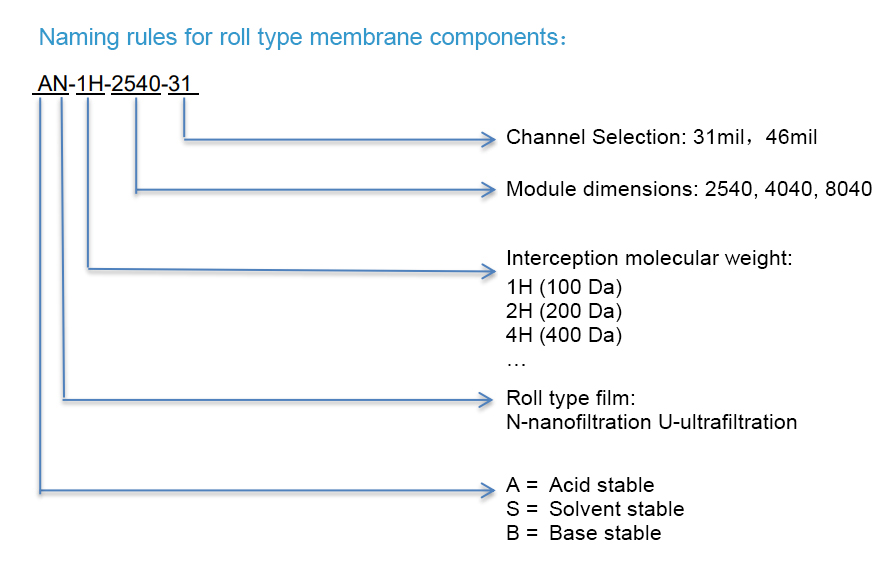

| Product | Application environment | Membrane model | Interception molecular weight | PH range |

| Nanofiltration membrane | Acid | AN-1H | 100 | 0 – 12 |

| AN-2H | 200 | 0 – 12 | ||

| AN-4H | 400 | 0 – 12 | ||

| Alkali | BN-1H | 100 | 3 - 14 | |

| BN-2H | 200 | 3 – 14 | ||

| Organic solvents | SN-1H | 100 | 2 - 12 | |

| SN-2H | 200 | 2 – 12 | ||

| SN-4H | 400 | 2 – 12 | ||

| Ultrafiltration membrane | Acid | AU-25H | 2500 | 0 – 12 |

| AU-10K | 10000 | 0 – 12 | ||

| Organic solvents | SU-25H | 2500 | 2 – 12 | |

| SU-10K | 10000 | 2 – 12 |

Step 1: Preliminary testing By understanding the complete composition of the solution and the previous use of other filter membranes, we can conduct a simulation and provide Predict the separation results as accurately as possible. Therefore, please make sure to fill out a report on the full composition of the material liquid when consulting the project Table. This table lists a series of parameters required for membrane simulation measurements, based on which application development experts can Provide you with a preliminary analysis test as accurately as possible. Step 2: Laboratory testing After completing the initial analysis, we suggest conducting further laboratory testing. We have multiple sizes of solid Film inspection can be used for feasibility testing. Step 3: Concept Verification We work with clients to preliminarily evaluate business application cases and analyze the potential benefits of expected investment costs. Step 4: Factory testing Through cooperation with engineering companies, our partners will design and build a testing system for the client company. Step 5: System installation and operation Finally, the engineering company will assist in configuration to ensure the comprehensive installation and operation of the entire system.